The three-axis platform is suitable for building and manufacturing automatic screw machines, glue dispensing machines, soldering machines, inkjet printers, material arraying machines, engraving machines, coding machines, toy organizers, and plasma cleaning machines.

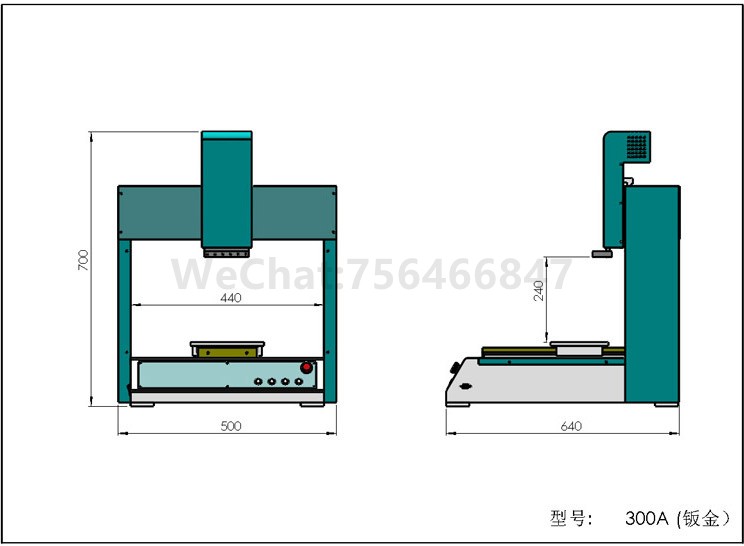

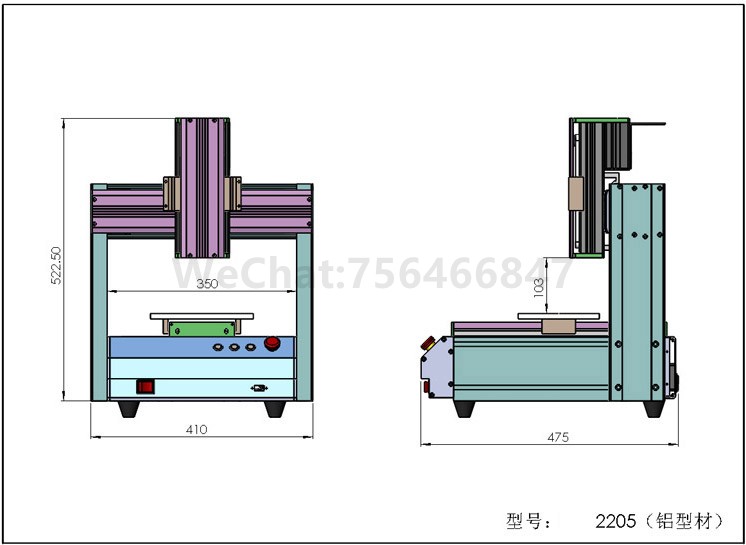

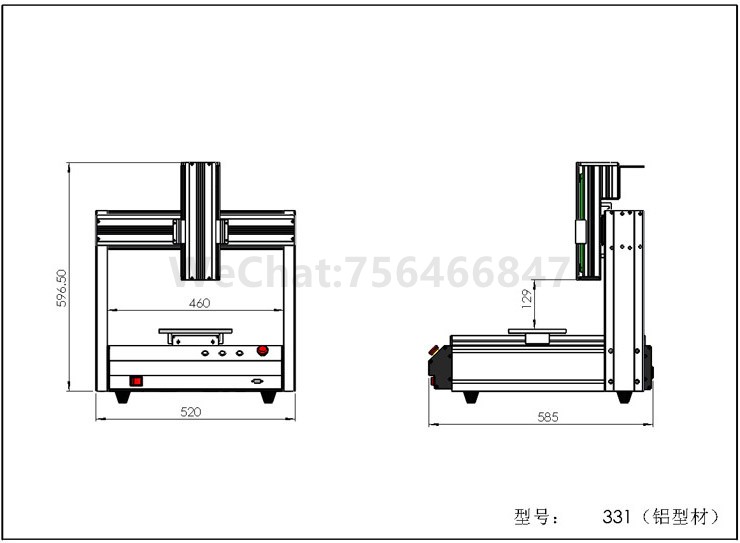

The three-axis platform's main frame is constructed of high-titanium aluminum, providing high strength and stable high-speed operation. The surface is specially treated with a non-stick adhesive for easy cleaning. The metal pushbutton switch is highly sensitive and durable. The machine's base is thickened and insulated, and it is supported by four large, adaptive disc feet.

Applicable Industries

This 3D platform is suitable for building and manufacturing automatic screw machines, glue dispensers, soldering machines, inkjet printers, material arraying machines, engraving machines, coding machines, toy organizers, plasma cleaning machines, and other industries.

Product Advantages

The main unit of the 3D platform is constructed of high-titanium aluminum, providing high structural strength and stable high-speed operation. The surface is specially treated with non-stick adhesive for easy cleaning. Metal pushbutton switches are highly sensitive and durable. The machine's base is thickened and insulated, and it is supported by four large, adaptive disc feet.

Advantages

1. DIY mode allows for flexible configuration, enabling screw tightening, gluing, soldering, engraving, grinding, and deburring platform construction.

2. A molded aluminum alloy four-axis (or multi-axis) machine frame design is rational and practical.

3. Simple and convenient operation and installation, with user-friendly operation.

4. Path program files can be uploaded/downloaded for convenient data management and storage.

5. Intelligent teaching mode, PC mode, and visual mode can be freely configured.

6. Features include continuous interpolation of points, lines, surfaces, arcs, circles, and irregular curves.

7. Italian timing belts, Taiwanese lead screw guides, and Japanese imported motors ensure stable, reliable, and durable quality.

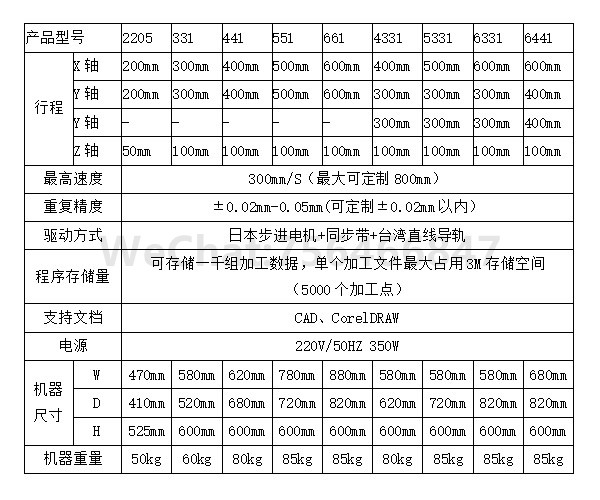

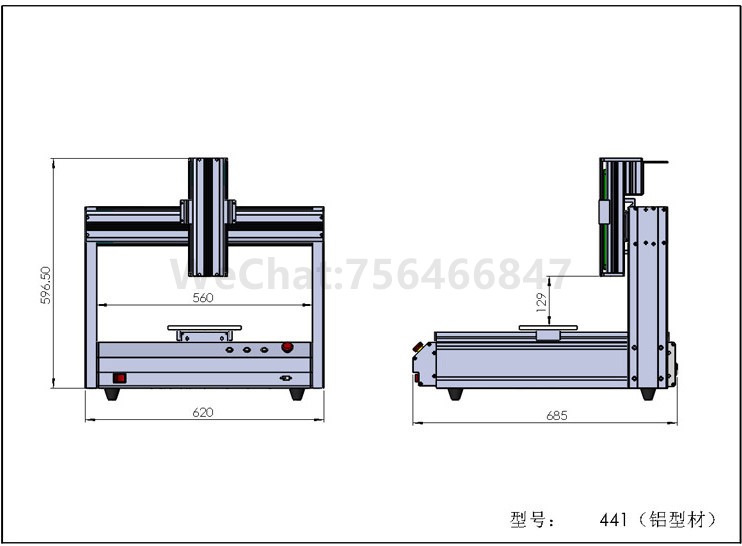

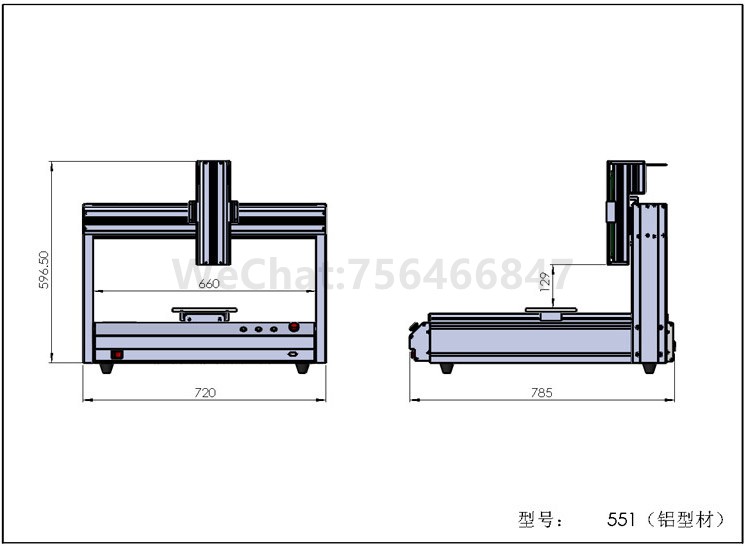

Machine Parameters

COMPANY:Shenzhen Jietongtai Technology Co., Ltd

Contact:Mr. Zhou

Tel:13410974163

Phone:15338087819

Email:mail@jietongtai.com

Add:A3 Floor, Hongda Phase III Factory, No. 9-2 Xingye 3rd Road, Fenghuang Community, Fuyong Street, Bao'an District, Shenzhen